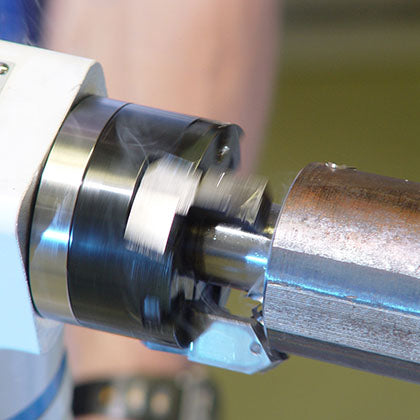

ID Mount Bevellers 1/2" - 4"

Description

The solution when space is limited! Only very limited space is often available between welded boiler pipes. The compact body design of BRB machines is optimized for the application in question to provide the operator with the best possible access in every position and is therefore the best solution for pipe end and tube sheet joint preparations in boiler, tank and apparatus construction.

Features

New, Variable Clamping Systems

- The "NC" clamping system, with its clamping wedges firmly anchored in the mandrel, is ideal for applications where no foreign bodies must enter the inside of the pipe or container. The "NC" clamping system provides extra safety, particularly for vertical applications.

- The "Standard" clamping system has been optimized in terms of stability and reliability. You can still use this system.

Additional Benefits

- Precise and reproducible weld prep profiles

- Handy and compact design

- Maximum performance and lightweight

- Tool bits with up to 4 cutting edges and high-performance coating

- Up to 3 tools can be used at the same time

- Quick clamping system for tools with easy adjustment

- Adjustable air outlet

- Easy to change tools

- Tools adaptable on all BRB machines

- Low noise level

Specifications

| Model | Power Source | Pipe ID Min. | Pipe OD Min. | Power [KW] / [HP] | Weight (kg) |

| BRB 2 Kit 2 | Pneumatic | 19.1-38.0 | 23.0-62.0 | 0.38/0.51 | 5.6 |

| BRB 2 Kit 2 | Pneumatic/Auto | 19.1-38.0 | 23.0-62.0 | 0.38/0.51 | 5.6 |

| BRB 2 Kit 2 | Electric | 19.1-38.0 | 23.0-62.0 | 0.5/0.67 | 4.7 |

| BRB 4 Kit 3 | Pneumatic | 35.0-108.0 | 114.3 | 1.0/1.34 | 9.3 |

| BRB 4 Kit 3 | Pneumatic/Auto | 35.0-108.0 | 114.3 | 1.0/1.34 | 13.3 |

| BRB 4 Kit 5 | Pneumatic | 19.1-108.0 | 114.3 | 1.0/1.34 | 9.3 |

| BRB 4 Kit 5 | Pneumatic/Auto | 19.1-108.0 | 114.3 | 1.0/1.34 | 13.3 |