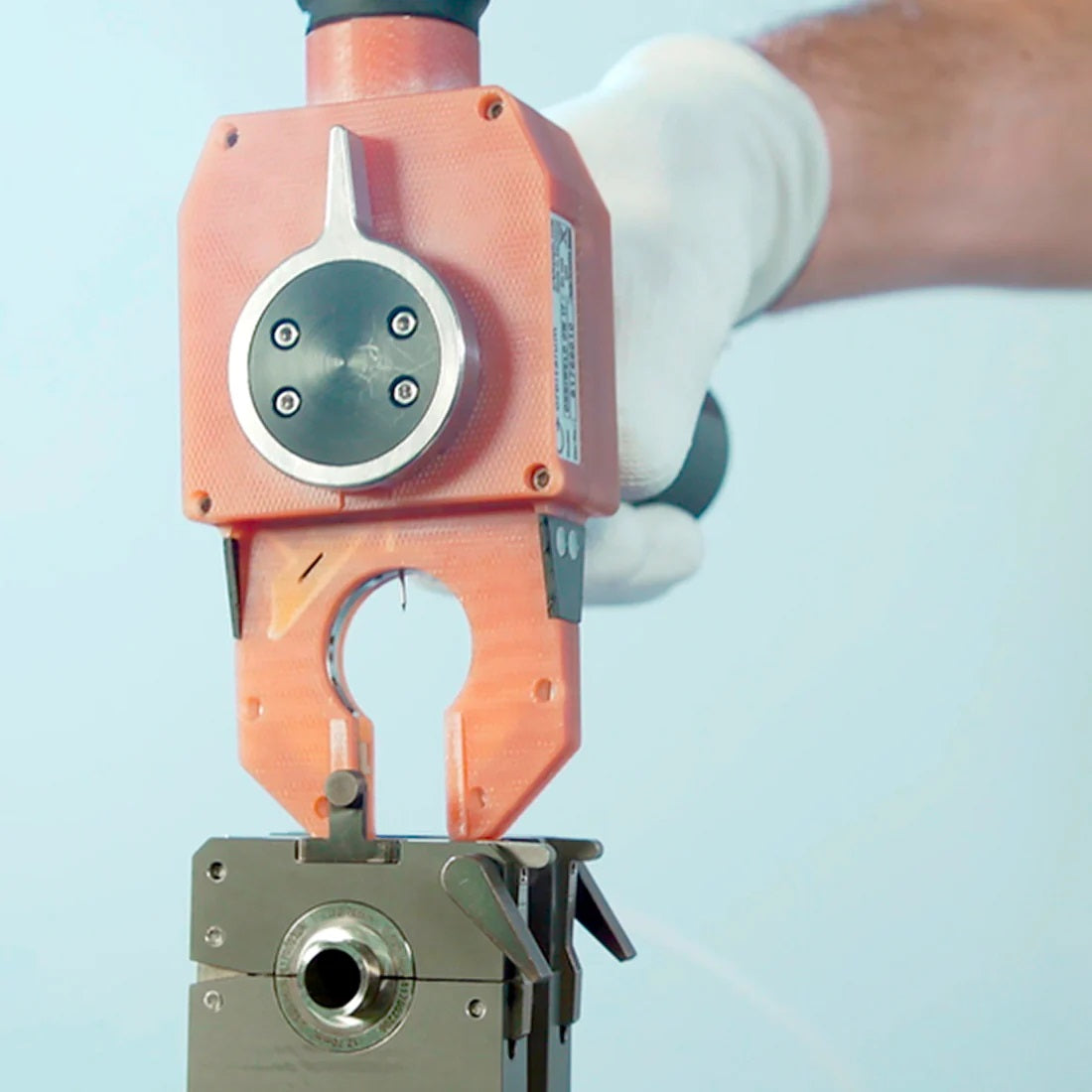

OW17 Gas Cooled Weld Head

Active-cooled orbital weld head for tubes in semi-conductor production:

With its removable clamping cartridge, integrated control elements and active cooling, the ORBIWELD 17 – or OW 17, for short – clearly stands out in comparison to conventional systems from the competition. This makes it possible to weld thin tubes like those used in semi-conductor production easily, quickly, reliably and – above all – with high quality.

Following intensive research, this orbital weld head was improved in comparison to commonly available weld heads in crucial areas so as to optimize handling, welding results and production times. As the OW 17 is compatible with the current market standard, users can easily switch over to the new technology.

The orbital weld head is specially designed for small tube diameters from 3.0 mm to 17.2 mm (0.118" - 0.677") and wall thicknesses up to 1.62 mm (0.064")

like those used in production systems from the semi-conductor industry.

The OW 17 features a removable clamping cartridge which can be very easily positioned around the tubes to be welded in inline assembly at the construction site or prefab production of modules in the workshop.

Thanks to its compact, handy design, it can be neatly positioned and perfectly aligned to the weld point, thus enabling use in confined spaces. When the cartridge is in place, the weld head is inserted and secured in the cartridge and welding can begin. The operating elements required for starting, stopping, gas flow and electrode changes are integrated in the handle of the head.

An LED informs the welder of the operating conditions, like readiness to weld and the active process. During installation work, a second operator is not required at the welding power supply, which may not be located nearby.

Integrated active liquid cooling protects the OW 17 head from overheating and enables a long operating duration and therefore shorter work cycles. The head of the OW 17 is designed for 1.0 mm (0.039") and 1.6 mm (0.063") electrodes and thus ensures a consistently high electrode service life when welding thicker walls. This orbital weld head can also be used with COAX tube systems, for example. This saves the user a second orbital weld head.

The included adjustable electrode distance gage makes it easier for the operator to set up the electrode; an insertion gage which is permanently attached to the cartridge and thus cannot be lost ensures precise positioning to the tube joint to be welded.