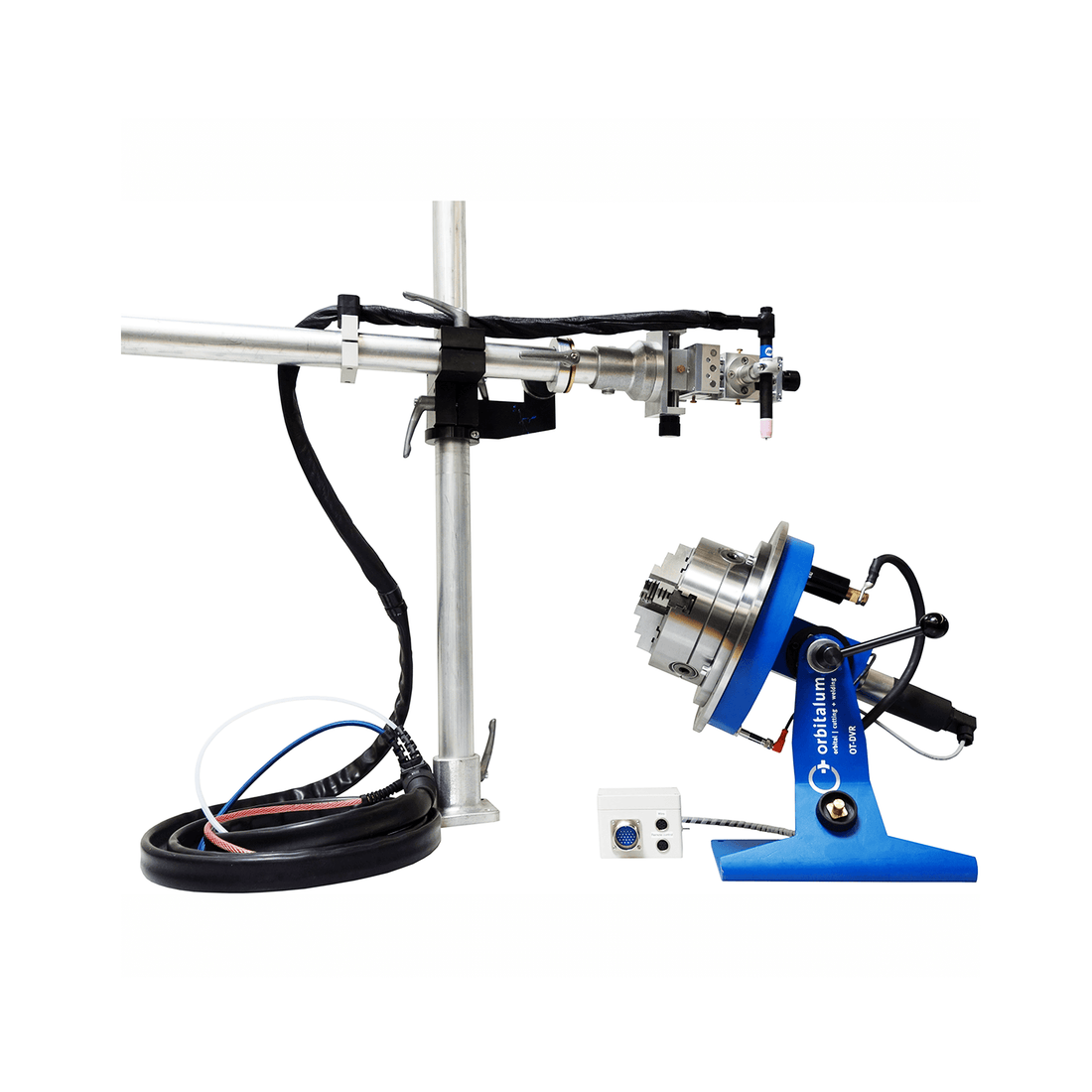

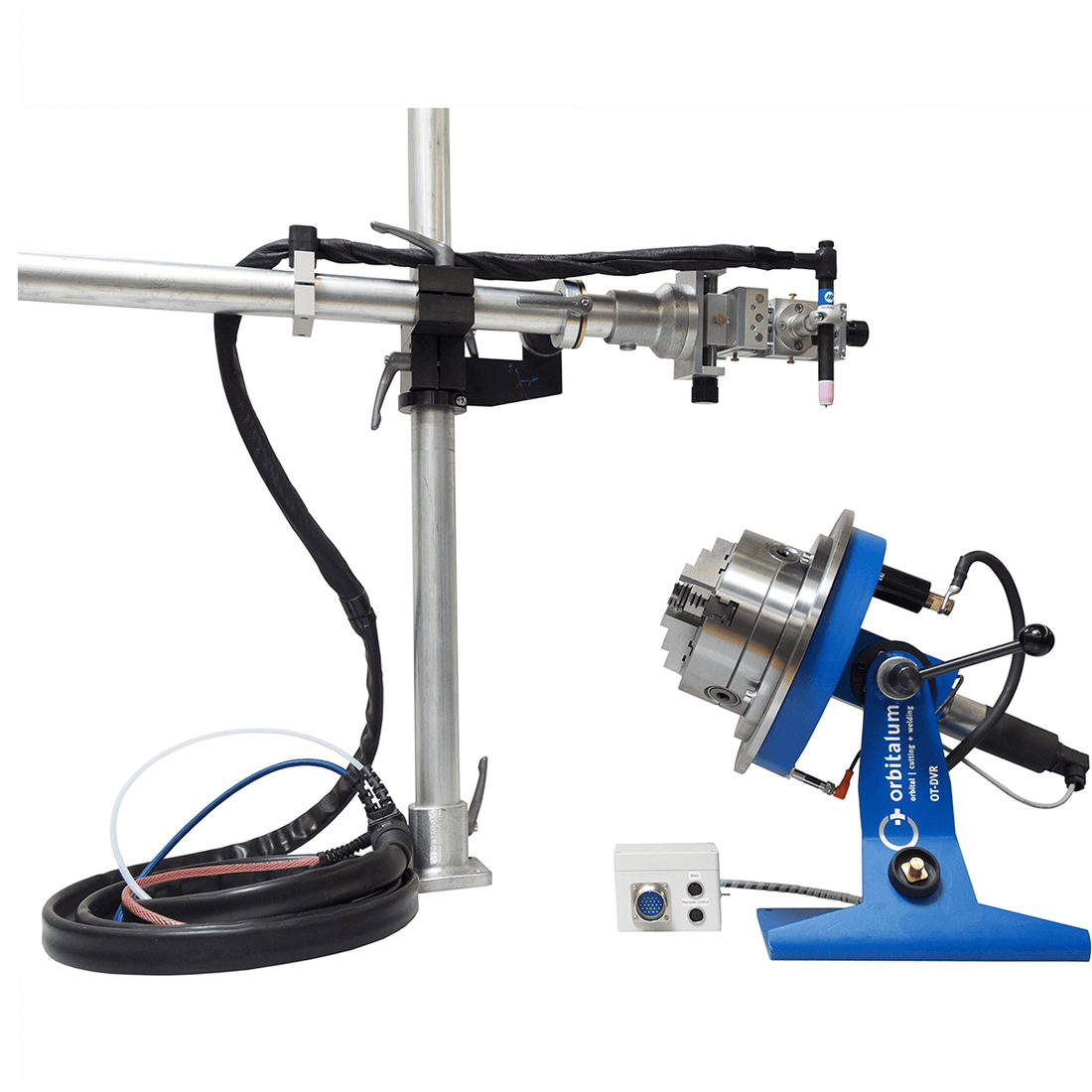

DVR Welding Turntable

Description

The DVR Welding Turntable is a reliable and efficient solution for the welding of rotating workpieces, short molded parts and fittings. They are available in different versions and can be equipped with various options as required. Their stable construction allows even massive workpieces to be positioned without any problems, while the powerful clamping feature clamps without any deformation of the workpiece. While the quality of the weld seam remains at a constantly high level, the physical burden for the operator is reduced significantly. The result: Maximum safety and productivity.

Some features include:

- Stepless tilting up to 90°

- High-quality three-jaw chuck

- 3-axis torch support

- Modular extendable structure

- The direction of rotation selection

- Cold wire retrofitted optionally

- Wire equipping quick change system

- Liquid-cooled torch

Features

- Turntable can be tilted steplessly from 0 to 90°

- Centered clamping three-jaw chuck made of hardened and polished steel

- Three-jaw lathe chuck available for different clamping ranges

- Robust steel structure, excellently suited for use even under extreme process conditions

- Stable, swivel torch stand

- Three-coordinate torch support

- Ball-joint holder for TIG machine welding torch

- Liquid-cooled TIG torch head (200 A)

- Remote controls for higher operator comfort (available optionally)

- Cold-wire supply for wire 0.8 mm (0.031") and 1.0 mm (0.039") for welding with cold wire (available optionally)

- Modern functional design

- Arc gap control unit for automatic controlling and holding of the arc gap (AVC = Arc Voltage Control)

- Shorter welding times at constant high quality

- Compatible with all power sources of the ORBIMAT CA series

Orbital Welder Handbook - Understanding the Invest

Orbital Welder Handbook - Understanding the Invest