Collaborative Welding

Smart + Simple

Where state-of-the-art technology meets user friendly adaptability

Collaborative Welding Robot (Cobot)

Needing to grow your business but struggling to recruit staff?

Empower your existing workforce with a Collaborative Welding Robot (COBOT)

- Worlds easiest to use COBOT system

- MIG Welding System

- Integrated turnkey package

- Kept in-stock in Australia

- App-based software that anyone can use

---

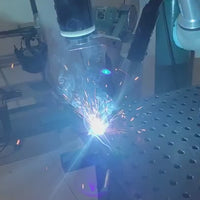

Designed for the simple, repetitive jobs found in any welding workshop, the Cobot frees up time for welders to focus on the more complex jobs.

Welders aren't interested in complex programming and robotic jargon, so the Collaborative Welding Robot is designed to enable anyone to use it with very little downtime. The welder simply enters the welding parameters with a press of a button.

Included in the Cobot Welder package is:

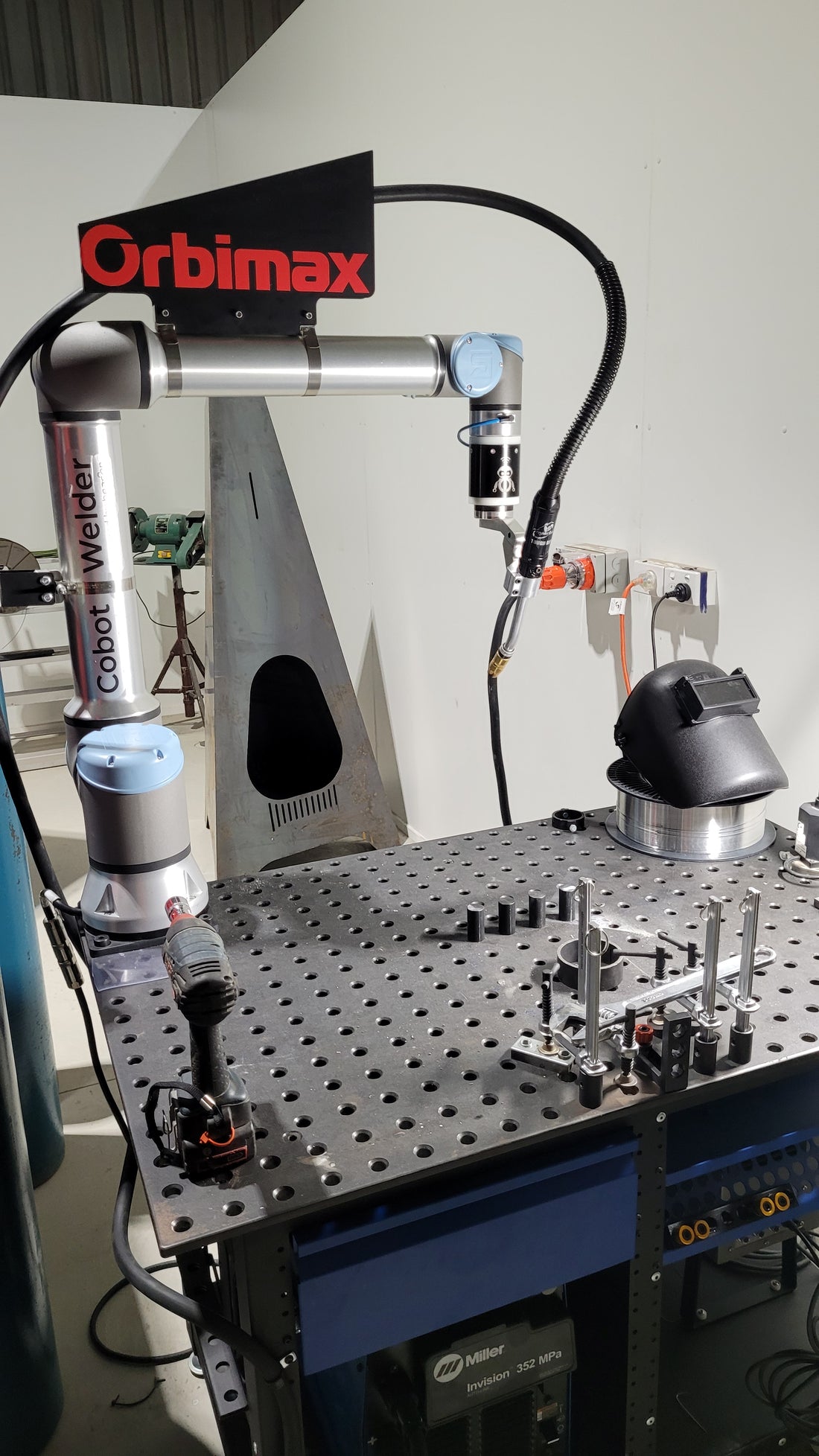

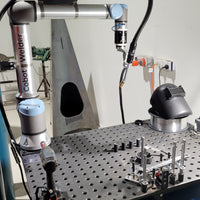

- Universal Robots UR10e Collaborative Robot (1.7m reach or 3m from centre point)

- Miller Cobot Welding Package, including an Invision 352 MPa pulse‚ MIG welder and S74 wire feeder

- Tregakiss Tough MIG Welding Gun

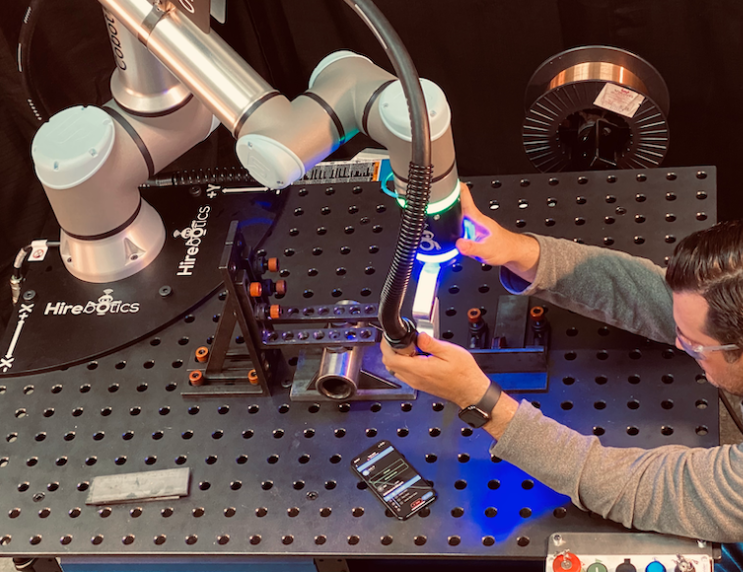

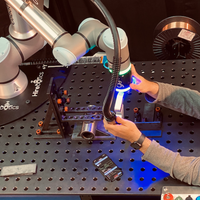

- Hirebotics' Smart Puck for software-free teaching

- Siegmund 1200mm x 812mm (48" x 32") welding table

- Operator panel with emergency stop for quick program start

What is Cobot?

Learn More

Work Smarter

Is Cobot the right tool for you?

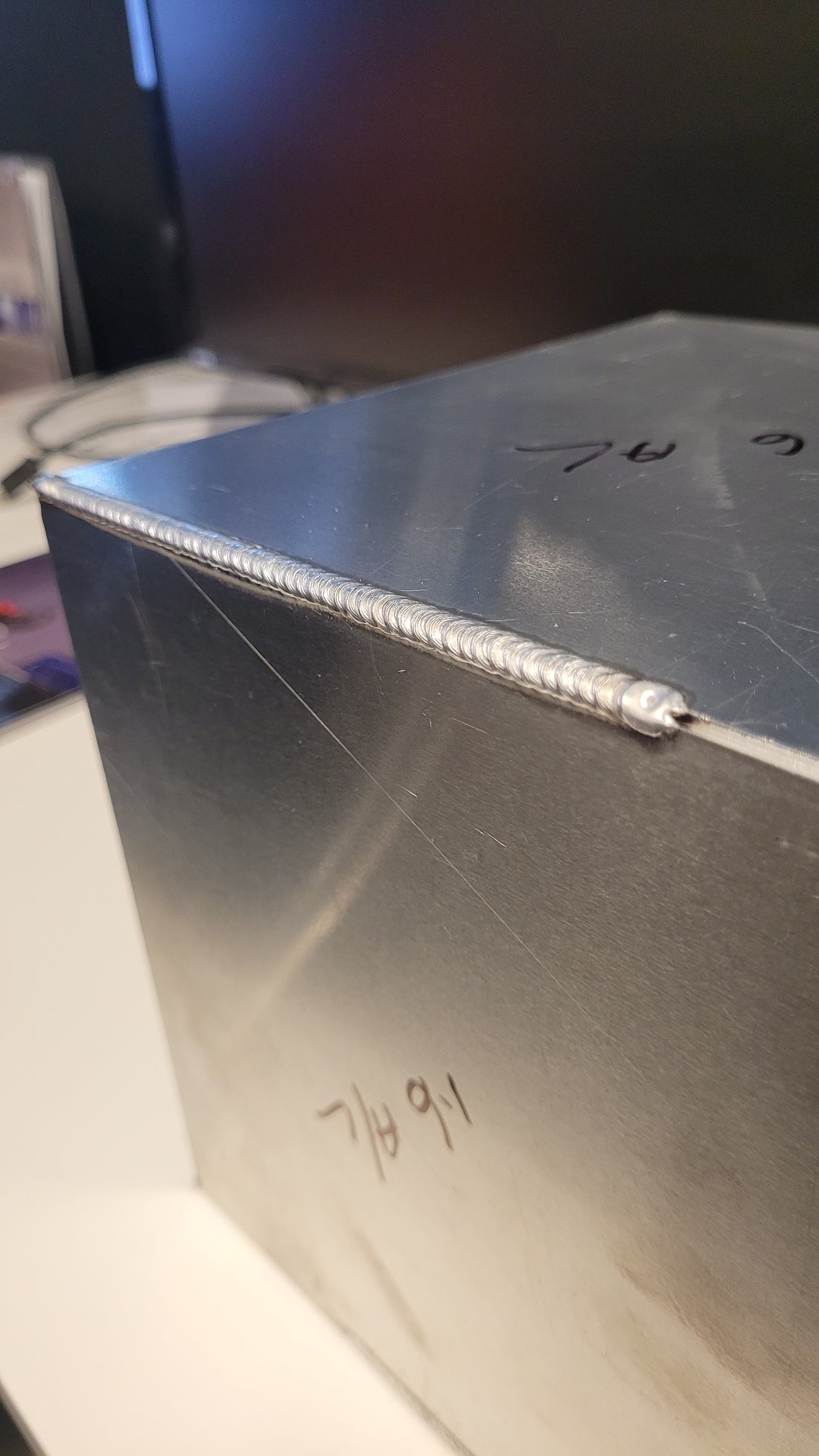

Manual welding has become the industries number one production hold-up. Cobot will complete tasks faster and deliver unparalleled quality every time.

80% of Australian manufacturers experience staff and skills shortages. A Cobot will reduce labour costs and achieve the same output as 4 employees.

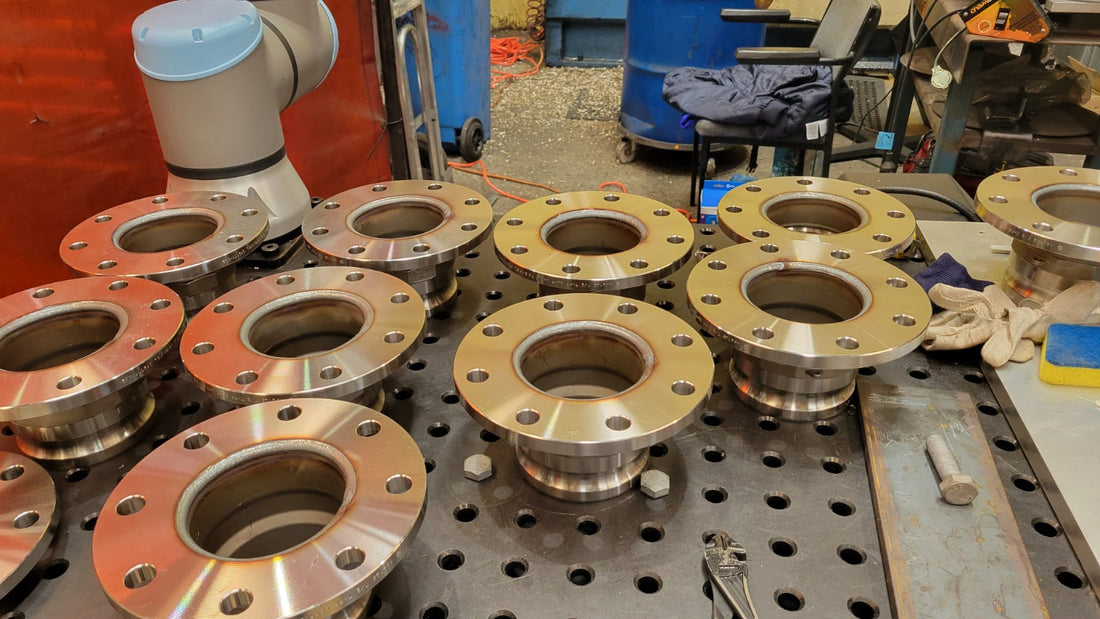

Manufacturers often use skilled welders to complete repetitive, or menial tasks. A Cobot will automate simple repetitive welds with quality and precision.

Non-compliance with safety standards can result in significant consequences. Implementing Cobot welders with in-built safety sensors will reduce risk and human error.

Orbimax

Video Library

Watch our short videos to learn more about how Cobot works and is being used in the industry.

Australian Manufacturing Week

The Cobot is so simple to use even a child can operate it. Watch Cobot being demonstrated at Melbourne's Australian Manufacturing Week (2024).

Product Demonstration

Watch Daniel Adams, Principle Engineer at Hirebotics demonstrate how easy the Cobot is to use with a smart phone as the controlling device.

Solving the Welder Shortage

Warren Earl, Vice President of IMS in the United States, talks about how they use Cobot to tackle productivity and complexity issues.

Customer Testimonial

“As a business owner, we have seen the game-changing impact that the Cobot Welders have had on our business. With their ability to work around the clock, these machines have the output of multiple staff members and significantly increased our productivity and efficiency.

The precision and speed of the automation, combined with the versatility of human skill, has led to a reduction in errors and waste, and a boost in our bottom line.”

- JOHN HARMAN BFSM

Learn More

Cobot vs Robot: What's the difference?

Robots operate at high speeds, so extensive safety measures are required. As a result, they are often zoned off and work independently from users. Robotic welders also require larger investments and specialised training.

The Cobot has a lower operating speed and more safety measures in place to remove the potential for accidents and hazards. This allows the user to work alongside the Cobot, making it a collaborative part of the team and another tool in your workshop.

Speak to

The Orbimax Team

Our highly-skilled team of experts will help you swiftly integrate Cobot into your operation, and work closely with you over the longer term to increase capacity, streamline processes and improve your bottom line.

Brandon Arnot | Sales Manager

Aaron Hollingworth | Operations Manager

Lloyd Thrush | Client Services Co-ordinator

cobot

Key Benefits

• Reduce labour costs

• Mitigate staffing challenges

• Negate the need for specialised training

• Reduce errors and waste

• Increase productivity, speed, accuracy and efficiency

• Reduce energy costs

• Reduce potential hazards and improve safety