GF6 Orbital Pipe Cutting and Bevelling Saw

Description

The basic requirement for the productive and high-quality welding of pipes with automated welding technology is a precise, right-angled and burr-free cut as well as a perfectly beveled pipe end. The Orbitalum pipe saws cut and bevel high-alloy steel (stainless steel), low- and unalloyed steel, plastics, casting materials and non-ferrous metals easily and in just seconds, using the "Planetary Cutting" method. The powerful clamping is effected without any deformation of the workpiece. The GF6 cuts any pipe or tube from 1" to 6".

Features

- Square, burr-free and cold machining process

- Deformation-free clamping system for tubes and pipes

- Optimum preparation for the automated welding process

- Sturdy design with powerful drive

- Unique and automated orbital cutting process

- Simultaneous or separate cutting and bevelling

- Cost-effective, increasing productivity

- Long tool life

- coloured coated components for improved sliding properties and protection against corrosion

- Stainless steel clamping attachments for protection against contact corrosion included

- Reduced operator impact by optional feed module AVM or MVM for an automated or manual cutting process

- Locking mechanism prevents unauthorised usage and theft

- An ergonomically-designed motor handle for a safe and comfortable operating position, which also enables easy cutting of elbows

- Integrated line laser to determine the cut-off point

- 2 position clamping jaws to reduce chatter and enable the smaller length of pipe to be machined

- Multifunctional tool for all adjustments on the machine

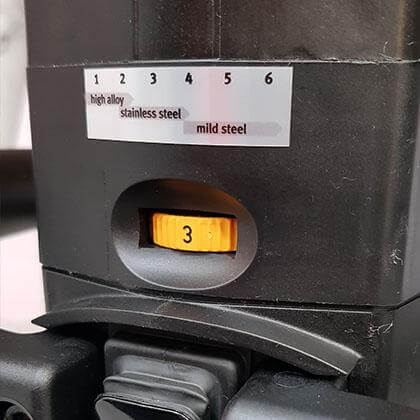

- Optimised speed range (40-215 rpm), ideal for cutting high-performance materials (Hastelloyƒâ€š‚®, P91, etc.)

- Swivel cable with a quick-disconnect coupler: for easy and comfortable replacement of the power cable

- Optimised saw blade guard protects the user against flying chips and comes with a measuring port

Specifications

| Item | GF6 |

| Clamping Range | 21.3 - 168.3 mm |

| Pipe ID Min. | 13 mm |

| Wall Thickness | 1.5 - 15 mm |

| Weight | 92.7 kg |

Download

WHAT ARE GF SAWS AND HOW DO THEY WORK?

GF saws are orbital pipe cutting tools, which use the "Planetary Cutting" method of rotating around pipe to cut it rather than cutting the whole way through from one point.

By rotating around the pipe while it's held in a fixed position with a powerful clamping system, the GF saws remove the chance for a cut to fall off the square, ensuring a precise, right-angled and burr-free cut.

GF saws also have the capability to bevel a pipe, with an extra saw that can be used separately or at the same time as a normal saw, cutting pipe preparation times in half.

SQUARE, BURR-FREE CUT WITH A PERFECT BEVEL

The unique, planetary cutting method of the GF saws creates a square, burr free cut.

Add to this Orbitalum's specialised saws with bevelled teeth that can be used separately or in conjunction with the cutting saws to create a perfect bevel, and you have one machine that can do all your pipe preparation for you.

UNIQUE PLANETARY CUTTING METHOD

With the planetary cutting method, the saw blade rises into the cutting are and is driven orbitally around the tube.

This provides the advantage of a small saw blade being able to cut a large diameter tube without creating heat.

DEFORMATION FREE CLAMPING

A powerful clamping mechanism lets you cut any variety of tube easily and without the worry of deforming your pipe.

The dual position clamping jaws reduce chatter and enable smaller lengths of pipe to be machined, while stainless steel clamping attachments protect against contact corrosion.

ERGONOMIC MOTOR HANDLE

A dual sided, easy grip handle alllows for better ergonomics to provide for a safer, more comfortable operating position.

REDUCED OPERATOR FATIGUE

As well as a manual cutting mode, Orbitalum GF Cutters offer an automated cutting process feed module, that allows operators to set the machine up and leave it to complete the cut on its own.

LASER PRECISION CUTTING

An integrated laser-precision line makes sure you always cut exactly where you intend to.

GFX6 Spec sheet

GFX6 Spec sheet