What is Cold Cutting?

Cold Cutting refers to cutting pipe without the use of heat from a torch (hot cutting) where open flame is used.

Why Cold Cutting?

A series of serious incidents have contributed to the development of cold cutting technology to advance pipeline repair safety. A main contributor of these incidents is the presence of hydrocarbons (a basic building block of energy products) in pipelines that creates a potentially hazardous situation when pipeline repairs, modifications or decommissioning are needed.

Cold cutting machines are designed to eliminate the hazards associated with thermal cutting, and are increasingly being specified for their inherent safety advantages. Their development reflects the priorities in pipeline repairs as follows:

- Safety - is first and foremost as the primary consideration before any pipeline project is planned. This covers the safety of the operators of the tools and the safety of the product flowing through the pipeline.

- Time – time is a critical factor affecting pipeline repairs when the community is relying on you to consistently provide safe sources of water, gas and other infrastructural elements.

- Money – there is always a budget that needs to be kept in so it is important that while cold cutting machines are both safe and save time, they need to have a good ROI.

Benefits of Cold Cutting:

-

Prevention of HAZ

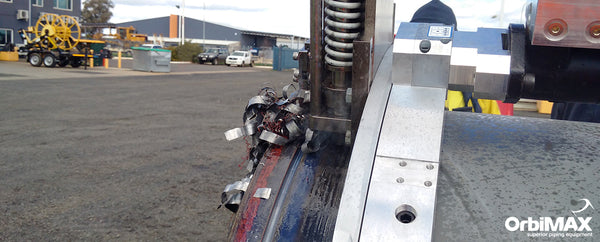

Undesirable HAZ (Heat Affected Zone) No HAZ after cold cutting - the perfect weld prep!

A significant advantage of the cold cutting process over torch cutting is the prevention of a HAZ (Heat Affected Zone). A HAZ is created when extreme temperature such as those produced by plasma or acetylene torches, is applied to a pipe. This changes the molecular structure of metal itself and often alters its properties to detrimental effect. -

Eliminates need to grind

Torch cutting requires a second step of hand grinding to create a suitable weld ready surface. This is a difficult, laborious and time consuming process that involves inerting the pipeline with nitrogen gas to prevent combustion. Eliminating these steps saves a considerable amount of time, cost and labour. -

Fast method

Time is a critical factor in pipeline repairs where environmental concerns and prior experiences demonstrate that faster is better to stop or prevent leaks and spills that harm the environment. This means that any tool that can perform its task faster is well worth investing in. -

Safe

Dangers of the open flame produced by a gas torch is eliminated. In addition, airborne contaminants that are introduced into the environment by torch cutting are no longer a potential health hazard.

Cold Cutting Machines:

Most pipeliners today specify the split frame (clamshell) rotating ring pipe cutter that splits in half to mount around the OD of inline pipe. There are various configurations of split frames available such as:

- Low Clearance models - designed to balance weight, clearance and portability issues

- Heavy Duty models - designed for large diameter or heavy wall pipe

Introduced in 1949, the Trav-L-Cutter® was the first pipe cutting machine that utilised the cold cutting method.

Designed to crawl around the pipe on its mounting chain, the Trav-L-Cutter® utilized a high speed milling head to simultaneously cut and bevel the pipe. The two main benefits of this were:

- Flame was eliminated - an obvious safety benefit

- Created precision beveled surface ready for welding

Recommended Cold Cutting Machines:

|

Trav-L-CutterThe Trav-L-Cutter is ideal for severing and beveling all common pipe materials, wall thicknesses and sizes from 6” (DN150) on up. Its special milling blades, leaves the pipe ends with a fine milled finish with no heat affected zone (HAZ). |

|

DynaPrepThe DynaPrep® Split Frame is a cold cutting tool that splits in half to mount over inline pipe. It is designed for cutting, bevelling, facing, counter boring and flange facing on heavy wall pipe including high alloy material. |

|

GFX 6.6 Pipe Cutting & Bevelling MachineThe ideal solution for cutting of thin-walled tubes, typical to food processing, beverage, pharmaceutical and chemical industries where it's rugged design ensures a long product life. |

|

Large Diameter Split FrameThe Large Diameter Split Frame (LDSF) is designed for cold cutting, beveling, facing and counterboring on large diameter pipes, vessels and flanges. Each machine covers a 15in (381mm) diameter range. |

|

Guillotine SawGuillotine pipe saws are designed to cold cut 2” through 32” (DN50-800) pipe, as well as solids such as bar stock, rails and beams. They’re strong yet light, simple to mount, simple to operate and simply bulletproof. |

Unique Features of the Split Frames:

-

Machining Abilities

Split Frames are able to cut and bevel simultaneously and are capable of machining much faster and more accurately than the milling process allows. They allow you to produce the compound bevels and complex “J” prep specified by leading welding equipment manufacturers, which cannot be done using thermal cutting and grinding. -

Complete Machining System

Machine accessories enable the Split Frames to tackle just about any onsite machining project likely to be encountered in the field. Accessories including tool slides (that hold the tooling) and tooling (cutting bits) are available to cut, bevel, counterbore (machine the inside of the pipe) and face flanges. -

Speed & Quality of Cut

Split Frames are designed to set up quickly, to cut quickly and to cut and bevel with great precision. Destructive cutting is easy no matter the tool used, but what really counts is the critical cut needed for fit up, nicknamed the “money cut”. This cut must be exactly correct to deliver the goods, time in and time out. -

Out-of-Round Tooling

The pipe generally used in pipelines is a medium to large diameter pipe with relatively thin walls of about .5” (12.7mm) or less. This type of pipe is seldom perfectly round and can be egg shaped, a condition known as “out-of-round”. To ensure consistent contact of the tooling, spring tracking or out-of-round (tool) slides are available. They use springs to locate a wheel that rides along the contour of the pipe, preventing the tooling from diving in and out of the work. Out-of-round slides also speed the set-up of the machine by making it less critical that the machine be perfectly centred on the pipe. -

Tracking Slides for Uniform Land

The land is the most important part of the weld prep. If the land is too narrow, then the welder may burn a hole through it. If the land is too thick, there may not be proper penetration to the base metal. Tracking slides allow the creation of a uniform land, which is that portion of the weld prep that accepts the critical weld root pass.

Questions? Call us on 1800 734 000