1. Alignment

- To get the best out of your Orbital Welder, and for consistent tube welds, alignment is king.

- Use a tube facer or a quality Orbital tube cutting saw and ensure any burrs are filed off with a fine file

2. Tiny tacks

- Small tacks are ideal for Orbital Welding. Every Orbital Welder will have a tendency to walk the weld pool around any protruding tacks

- If tacks are large or you are unable to get consistent small tacks with your Tig Welder, its best to get a small fine triangular file and run a groove through the centre of the tack. This will prevent the weld pool from dodging around the tack.

3. Clean tube

- All Orbital Welders love good quality clean stainless.

- Get some fine Scotch Brite abrasive and run it around both the inside and outside of the area you are going to weld.

- Before tacking and welding, be sure to run an alcohol wipe or some acetone around the tube. This will remove any potential grease or residue from the stainless which can cause inconsistency in the weld.

4. Perfect electrode grinding

- Orbital Welders work best with a consistent and properly ground electrode. Buy a tungsten sharpener. Most tungsten sharpeners will leave a straight grind on the surface of the electrode causing the arc currents to flow smoothly down onto the weld surface.

5. Accurate back-purging

- Having trouble getting a flat weld? Or are you getting suck-back internally? This is often directly related to the back-purge. Most tube welds will work best with a flow rate of approx. 5lpm internally. An inaccurate reading will cause inconsistencies and weld quality won’t be at 100% of its potential.

- Orbitalum machines have an integrated pack purging controller. These are a worthwhile investment if you own an Orbitalum machine.

6. Use quality gas

- Argon gas is accepted as a standard gas when Orbital Welding. Have you ever tried a 5% Hydrogen mix? (Often used in plasma welding). The presence of hydrogen in this gas causes the weld to be slightly hotter, allowing the machine to run with a slightly better duty cycle as less amps are required. Hydrogen mix is recommended if welding schedule 10 stainless steel with an Orbital Welder. Give it a go, you’ll notice an excellent shiny looking weld – inspectors love it!

- Its best to run 100% argon gas on the internal purge of the tube, most Orbital Welders will have this pre-programmed into the machine.

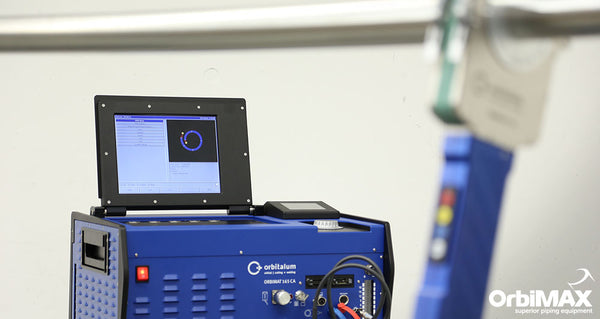

Watch an Orbital Welder Demo:

Questions? Contact Brandon on 1800 734 000 for Orbital Welding advice.