Struggle to get a square cut on stainless tube?

There are several best practices when it comes to getting a square and burr free cut on tube, without deformation.

What is your application..? Are you:

-

Cutting to prepare for a weld? See Use an Orbital Tube Cutting Machine below

-

Or cutting insitu pipework? See Use the mightly Cutting Blocks below

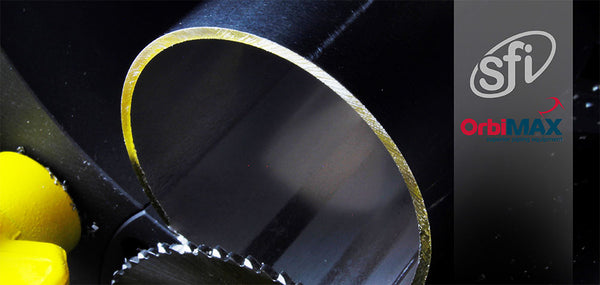

Use an Orbital Tube Cutting Machine

At the top of the podium for tube cutting sits orbital tube cutting machines, aka GF saws. These machines are known to get a square and bur free cut every time. Precise German engineering and a unique clamping system ensures a square cut with no deformation to the tube. The low speed cold cutting blade ensures accurate and defined cutting, leaving no burr, and making it perfectly ready to tack up your next weld.

These saws also have the ability to bevel the tube during the cut.

The most common George Fischer (GF) saws have a range of ¼” up to 20” on some machines and will cut and bevel up to 15mm wall thickness.

View GF Orbital Cutting Machine Product Details

Use the mighty Cutting Blocks!

When cutting insitu tube work, nothing beats a quality set of cutting blocks.

Cutting blocks are a simple clamping mechanism used to guide a recipro saw through tube for a square and deformation free cut. Quality cutting block sets are built to last, and are very easy to use. Check out the OrbiMAX Pro Series blocks. These have:

-

A built in lock to clamp over tube

-

A groove to clamp over the top of existing welds

-

An offset cutting slot to cut close to elbows

-

An extended cutting slot to improve blade life.

The OrbiMAX Pro Series cutting blocks are manufactured from case hardened steel, 100% Australian designed and made.

Coming in a standard set of all sizes from 1” up to 4”, the OrbiMAX cutting blocks are known as the best on the market. All sizes up to 6” are available.

View Cutting Block Product Details

More questions? Call 1800 734 000